K-INLINE-EJEKTTOREN VR

Inline ejectors »VR«, screw connection Product image

Product image

Properties

Properties

| Properties |

Vacuum generator with high maximum vacuum level (85% vacuum) No moving parts, which means no wear and no maintenance ultra small footprint, suitable for confined spaces minimal air consumption low noise |

| Application |

by screwing / plugging into the distribution beam direct attachment to the suction pad for handling various workpieces |

| Housing |

Aluminium eloxed (type VR) |

| Nozzle system |

Brass (type VR) |

| Connection |

Plug-in connection |

Description

Description

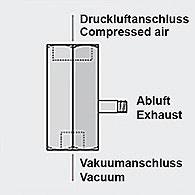

For vacuum generation directly at the point of use. For direct installation between the suction pad and the compressed air supply. Purely pneumatic vacuum generator that operates on the Venturi principle. Compressed air enters the ejector and flows through a nozzle. This results in a vacuum immediately behind the nozzle outlet, and air is drawn in through the vacuum inlet. This air and the driving air leave the ejector and enter the atmosphere via the exhaust air outlet.

Note

Note

Further information on request

Item

Item

Sort upwards

Sort downwards

Identification Identification |

Nozzlesize | Exhaustair outlet | Pneumatic connection | Vacuum inlet | degree of evacuation | air consumption suction (L/min) |

max. suction capacity (L/min) |

Length (mm) |

Operating pressure (bar) |

|---|---|---|---|---|---|---|---|---|---|

| K- 07 45 01 29 | 0,7 | M 5 male | G 1/4 IG | G1/8 female | 90 % | 21,0 | 14,0 | 35,0 | 5,0 |

| K- 07 45 01 30 | 0,9 | M 5 male | G 1/4 IG | G1/8 female | 89 % | 36,0 | 21,0 | 35,0 | 5,0 |

Disclaimer

Despite careful checking, we cannot guarantee the accuracy of all information included on this site, and we accept no liability.

All data and information in our online catalogue are based on currently valid standards and the regulations from the employer's liability insurance association. Product safety can only be guaranteed when our assembly instructions are carefully observed. Non-adherence to these regulations can affect product operation and functioning and result in a loss of warranty. Our warranty is only valid for HANSA-FLEX products. Our products are constantly subject to further development and technical changes are therefore possible.

Select language

Select language

Bulgarian (Български)

Bulgarian (Български)

Chinese (汉语)

Chinese (汉语)

Croatian (Hrvatski)

Croatian (Hrvatski)

Czech (Čeština)

Czech (Čeština)

Dutch (Nederlands)

Dutch (Nederlands)

Estonian (Eesti)

Estonian (Eesti)

French (Français)

French (Français)

German (Deutsch)

German (Deutsch)

Hungarian (Magyar)

Hungarian (Magyar)

Italian (Italiano)

Italian (Italiano)

Latvian (Latviešu)

Latvian (Latviešu)

Lithuanian (Lietuvių k.)

Lithuanian (Lietuvių k.)

Polish (Polski)

Polish (Polski)

Portuguese (Português)

Portuguese (Português)

Romanian (Română)

Romanian (Română)

Russian (Русский)

Russian (Русский)

Serbian (Српска)

Serbian (Српска)

Slovakian (Slovenčina)

Slovakian (Slovenčina)

Slovenian (Slovenščina)

Slovenian (Slovenščina)

Spanish (Español)

Spanish (Español)

Turkish (Türkçe)

Turkish (Türkçe)