TS L

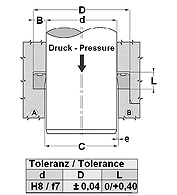

杆密封件, TS-L 产品图

产品图

属性

属性

| 结构类型 |

杆环槽圈 |

| 工作压力 |

达 400 巴 |

| 滑动速度 max. |

0,5 m/s |

| 温度 min. |

-30 °C |

| 温度 max. |

80 °C |

| 适用介质 |

矿物油 . |

| 装配 |

在开放环槽B内 在闭合环槽内 在开放安装腔内 |

| 原料 |

PUR |

| 应用 |

液压 |

描述

描述

高抗磨损强度

低压情况下极佳的密封效果.

快速负载更换

货品

货品

向上排列

向下排列

名称 名称 |

d (mm) |

D (mm) |

L (mm) |

|---|---|---|---|

| TS 06 14-L | 6,0 | 14,0 | 6,3 |

| TS 08 16-L | 8,0 | 16,0 | 6,3 |

| TS 10 16-L | 10,0 | 16,0 | 5,4 |

| TS 10 18-L | 10,0 | 18,0 | 6,3 |

| TS 12 19-L | 12,0 | 19,0 | 6,3 |

| TS 12 20-L | 12,0 | 20,0 | 6,3 |

| TS 12 23-L | 12,0 | 23,0 | 7,5 |

| TS 14 20-L | 14,0 | 20,0 | 5,3 |

| TS 14 22-L | 14,0 | 22,0 | 6,3 |

| TS 16 24-L | 16,0 | 24,0 | 6,3 |

| TS 18 24-L | 18,0 | 24,0 | 5,2 |

| TS 18 25-L | 18,0 | 25,0 | 5,7 |

| TS 18 26-L | 18,0 | 26,0 | 6,3 |

| TS 18 26-L1 | 18,0 | 26,0 | 9,0 |

| TS 18 28-L | 18,0 | 28,0 | 6,3 |

| TS 18 28-L1 | 18,0 | 28,0 | 8,0 |

| TS 20 26-L | 20,0 | 26,0 | 6,0 |

| TS 20 28-L | 20,0 | 28,0 | 6,3 |

| TS 20 28-L1 | 20,0 | 28,0 | 8,0 |

| TS 20 30-L3 | 20,0 | 30,0 | 5,0 |

| TS 20 30-L | 20,0 | 30,0 | 8,0 |

| TS 22 30-L1 | 22,0 | 30,0 | 6,3 |

| TS 22 32-L | 22,0 | 32,0 | 8,0 |

| TS 22 32-L1 | 22,0 | 32,0 | 9,0 |

| TS 24 34-L | 24,0 | 34,0 | 6,5 |

| TS 25 33-L | 25,0 | 33,0 | 6,3 |

| TS 25 33-L2 | 25,0 | 33,0 | 7,5 |

| TS 25 33-L3 | 25,0 | 33,0 | 8,0 |

| TS 25 33-L1 | 25,0 | 33,0 | 9,0 |

| TS 25 35-L3 | 25,0 | 35,0 | 6,3 |

| TS 25 35-L1 | 25,0 | 35,0 | 8,0 |

| TS 25 35-L4 | 25,0 | 35,0 | 9,0 |

| TS 28 34-L | 28,0 | 34,2 | 6,0 |

| TS 28 36-L1 | 28,0 | 28,0 | 6,3 |

| TS 28 36-L | 28,0 | 36,0 | 9,0 |

| TS 28 38-L | 28,0 | 38,0 | 6,3 |

| TS 28 38-L1 | 28,0 | 38,0 | 8,0 |

| TS 30 38-L1 | 30,0 | 38,0 | 6,3 |

| TS 30 38-L2 | 30,0 | 38,0 | 8,0 |

| TS 30 40-L | 30,0 | 40,0 | 7,5 |

| TS 30 40-L2 | 30,0 | 40,0 | 11,0 |

| TS 32 40-L1 | 32,0 | 40,0 | 6,3 |

| TS 32 40-L | 32,0 | 40,0 | 9,0 |

| TS 32 42-L | 32,0 | 42,0 | 8,0 |

| TS 32 42-L2 | 32,0 | 42,0 | 11,0 |

| TS 35 43-L2 | 35,0 | 43,0 | 6,3 |

| TS 35 43-L | 35,0 | 43,0 | 7,0 |

| TS 35 43-L1 | 35,0 | 43,0 | 9,0 |

| TS 35 45-L | 35,0 | 45,0 | 8,0 |

| TS 35 45-L1 | 35,0 | 45,0 | 11,0 |

| TS 35 50-L | 35,0 | 50,0 | 11,0 |

| TS 36 44-L1 | 36,0 | 44,0 | 6,3 |

| TS 36 46-L | 36,0 | 46,0 | 8,0 |

| TS 40 48-L1 | 40,0 | 48,0 | 6,3 |

| TS 40 48-L2 | 40,0 | 48,0 | 7,0 |

| TS 40 48-L | 40,0 | 48,0 | 9,0 |

| TS 40 50-L2 | 40,0 | 50,0 | 8,0 |

| TS 40 55-L1 | 40,0 | 55,0 | 11,0 |

| TS 40 60-L | 40,0 | 60,0 | 11,0 |

| TS 42 52-L | 42,0 | 52,0 | 9,0 |

| TS 45 53-L3 | 45,0 | 53,0 | 6,3 |

| TS 45 53-L | 45,0 | 53,0 | 9,0 |

| TS 45 55-L2 | 45,0 | 55,0 | 6,3 |

| TS 45 55-L | 45,0 | 55,0 | 8,0 |

| TS 45 55-L1 | 45,0 | 55,0 | 11,0 |

| TS 45 57-L | 45,0 | 57,0 | 10,5 |

| TS 49 65-L | 49,5 | 65,3 | 11,0 |

| TS 50 58-L | 50,0 | 58,0 | 9,0 |

| TS 50 60-L | 50,0 | 60,0 | 8,0 |

| TS 50 60-L2 | 50,0 | 60,0 | 10,0 |

| TS 50 60-L1 | 50,0 | 60,0 | 11,0 |

| TS 50 62-L1 | 50,0 | 62,0 | 9,0 |

| TS 50 65-L | 50,0 | 65,0 | 11,0 |

| TS 50 65-L1 | 50,0 | 65,0 | 12,5 |

| TS 55 63-L | 55,0 | 63,0 | 9,0 |

| TS 55 65-L | 55,0 | 65,0 | 8,0 |

| TS 55 65-L1 | 55,0 | 65,0 | 11,0 |

| TS 55 65-L2 | 55,0 | 65,0 | 13,0 |

| TS 56 66-L1 | 56,0 | 66,0 | 7,5 |

| TS 56 71-L | 56,0 | 71,0 | 12,5 |

| TS 60 68-L | 60,0 | 68,0 | 9,0 |

| TS 60 70-L | 60,0 | 70,0 | 8,0 |

| TS 60 70-L1 | 60,0 | 70,0 | 11,0 |

| TS 60 70-L2 | 60,0 | 70,0 | 12,5 |

| TS 60 70-L3 | 60,0 | 70,0 | 13,0 |

| TS 60 71-L | 60,0 | 71,0 | 9,0 |

| TS 60 72-L | 60,0 | 72,0 | 10,0 |

| TS 60 75-L1 | 60,0 | 75,0 | 11,0 |

| TS 61 69-L1 | 61,0 | 69,7 | 9,0 |

| TS 63 73-L | 63,0 | 73,0 | 11,0 |

| TS 63 75-L2 | 63,0 | 75,0 | 9,5 |

| TS 63 75-L1 | 63,0 | 75,0 | 11,0 |

| TS 65 73-L | 65,0 | 73,0 | 9,0 |

| TS 65 75-L | 65,0 | 75,0 | 13,0 |

| TS 70 78-L | 70,0 | 78,0 | 9,0 |

| TS 70 80-L | 70,0 | 80,0 | 8,0 |

| TS 70 80-L1 | 70,0 | 80,0 | 11,0 |

| TS 70 80-L2 | 70,0 | 80,0 | 13,0 |

| TS 70 82-L | 70,0 | 82,0 | 10,0 |

| TS 70 85-L | 70,0 | 85,0 | 12,5 |

| TS 75 83-L1 | 75,0 | 83,0 | 9,0 |

| TS 75 85-L | 75,0 | 85,0 | 8,0 |

| TS 75 85-L1 | 75,0 | 85,0 | 13,0 |

| TS 78 86-L1 | 78,0 | 86,0 | 9,0 |

| TS 79 87-L | 79,0 | 87,7 | 9,0 |

| TS 80 88-L2 | 80,0 | 88,0 | 9,0 |

| TS 80 88-L1 | 80,0 | 88,0 | 12,5 |

| TS 80 90-L | 80,0 | 90,0 | 8,0 |

| TS 80 90-L1 | 80,0 | 90,0 | 13,0 |

| TS 80 92-L | 80,0 | 92,0 | 9,6 |

| TS 80 95-L | 80,0 | 95,0 | 12,5 |

| TS 80 96-L | 80,0 | 96,0 | 10,5 |

| TS 85 93-L | 85,0 | 93,0 | 9,0 |

| TS 85 95-L | 85,0 | 95,0 | 8,0 |

| TS 85 95-L1 | 85,0 | 95,0 | 13,0 |

| TS 88 101-L | 88,9 | 101,6 | 10,5 |

| TS 90 102-L | 90,0 | 102,0 | 10,0 |

| TS 90 105-L | 90,0 | 105,0 | 12,5 |

| TS 95 103-L | 95,0 | 103,0 | 9,0 |

| TS 98 106-L | 98,0 | 106,7 | 9,0 |

| TS 100 108-L | 100,0 | 108,0 | 12,5 |

| TS 100 115-L | 100,0 | 115,0 | 13,0 |

| TS 105 113-L | 105,0 | 113,0 | 9,0 |

| TS 108 116-L | 108,0 | 116,0 | 9,0 |

| TS 110 125-L | 110,0 | 125,0 | 12,0 |

| TS 115 123-L | 115,0 | 123,0 | 9,0 |

| TS 116 124-L | 116,0 | 124,7 | 9,0 |

| TS 120 128-L1 | 120,0 | 128,0 | 12,5 |

| TS 125 133-L1 | 125,0 | 133,0 | 7,5 |

| TS 130 145-L | 130,0 | 145,0 | 16,0 |

| TS 135 143-L1 | 135,0 | 143,0 | 9,0 |

| TS 135 143-L | 135,0 | 143,7 | 9,0 |

| TS 135 150-L | 135,0 | 150,0 | 12,5 |

| TS 140 150-L | 140,0 | 150,0 | 12,5 |

| TS 154 162-L | 154,0 | 162,7 | 9,0 |

| TS 170 180-L | 170,0 | 180,0 | 11,0 |

订购指南

订购指南

我们可以短时间内完成20至510毫米直径密封件的加工。

免责声明

尽管经过了仔细审阅,但我们无法完全排除发生错误的可能,对所提供的信息数据本公司不承担任何责任。

本在线目录册的所有信息数据均以现行标准和同行工伤事故保险联合会的规则为依据。只有遵守了本公司的安装规程,才能保证产品的安全性能。若未遵守所有所述的规则,则会影响产品的功能安全性能,从而导致丧失保修资格。本公司的保修服务仅限于HANSA-FLEX产品。本公司的产品处于不断改进中,因此可能发生技术更改。

选择语言

选择语言

俄语(Русский)

俄语(Русский)

克罗地亚语(Hrvatski)

克罗地亚语(Hrvatski)

匈牙利语(Magyar)

匈牙利语(Magyar)

匈牙利语(Български)

匈牙利语(Български)

土耳其语(Türkçe)

土耳其语(Türkçe)

塞尔维亚语(Српска)

塞尔维亚语(Српска)

德语 (Deutsch)

德语 (Deutsch)

意大利语(Italiano)

意大利语(Italiano)

拉脱维亚语(Latviešu)

拉脱维亚语(Latviešu)

捷克语(Čeština)

捷克语(Čeština)

斯洛伐克语(Slovenčina)

斯洛伐克语(Slovenčina)

斯洛伐克语(Slovenščina)

斯洛伐克语(Slovenščina)

法语(Français)

法语(Français)

波兰语(Polski)

波兰语(Polski)

爱沙尼亚语(Eesti)

爱沙尼亚语(Eesti)

立陶宛语(Lietuvių k.)

立陶宛语(Lietuvių k.)

罗马尼亚语(Română)

罗马尼亚语(Română)

英语(English)

英语(English)

荷兰语(Nederlands)

荷兰语(Nederlands)

葡萄牙语(Português)

葡萄牙语(Português)

西班牙语(Español)

西班牙语(Español)