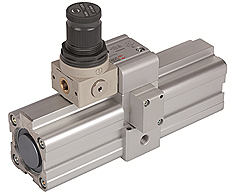

K-DVST MIT REGLER

Pressure booster with regulator Product image

Product image

Properties

Properties

| Input pressure |

2 - 10 bar |

| Output pressure |

Max. 20 bar (regulated: max. 16 bar) |

| Temp. range |

-10 °C to +50 °C (40 mm bore), -10 °C to +60 °C (63 mm bore) |

| Media |

Filtered, unlubricated or lubricated compressed air (if lubrication is used, it must be continuous) |

| Sealant |

NBR |

| Pressure regulators |

With plastic body |

| Housing |

Aluminium, anodised |

| Pipe |

Anodised aluminium jacket |

| Installation |

Any position, with 4 mounting holes |

| P2:P1 |

1:1 to 1.6:1 |

Description

Description

Pressure multipliers (boosters) allow a separate compressed air store with up to double pressure to be installed for selected devices in a compressed air system without an external energy source, i.e. it is possible to work with a maximum pressure of 20 bar in a standard 10 bar system (maximum ratio 2:1). This is achieved using a double piston, which is operated by a combination of integrated check valves in such a way that the booster works automatically until the target pressure is reached in a compressed air tank and is then automatically switched off. A tank is always required to build up the pressure and store the compressed air!

Note

Note

For information about calculating the filling times for different tank sizes, refer to the above-mentioned data sheet available on our website

Further information on request

Item

Item

Sort upwards

Sort downwards

Identification Identification |

Connection | Ø piston (mm) |

H (mm) |

L (mm) |

|---|---|---|---|---|

| K- 07 25 08 65 | G 1/8 | 40,0 | 139,0 | 194,0 |

| K- 07 25 08 67 | G 3/8 | 63,0 | 183,0 | 290,0 |

Additional information

Additional information

Accessories

Accessories

- K-ZUBEH ERSATZ LUFT BOOSTER

- Accessories / spare parts for Air-air-multiplicator (booster)

Disclaimer

Despite careful checking, we cannot guarantee the accuracy of all information included on this site, and we accept no liability.

All data and information in our online catalogue are based on currently valid standards and the regulations from the employer's liability insurance association. Product safety can only be guaranteed when our assembly instructions are carefully observed. Non-adherence to these regulations can affect product operation and functioning and result in a loss of warranty. Our warranty is only valid for HANSA-FLEX products. Our products are constantly subject to further development and technical changes are therefore possible.

Select language

Select language

Bulgarian (Български)

Bulgarian (Български)

Chinese (汉语)

Chinese (汉语)

Croatian (Hrvatski)

Croatian (Hrvatski)

Czech (Čeština)

Czech (Čeština)

Dutch (Nederlands)

Dutch (Nederlands)

Estonian (Eesti)

Estonian (Eesti)

French (Français)

French (Français)

German (Deutsch)

German (Deutsch)

Hungarian (Magyar)

Hungarian (Magyar)

Italian (Italiano)

Italian (Italiano)

Latvian (Latviešu)

Latvian (Latviešu)

Lithuanian (Lietuvių k.)

Lithuanian (Lietuvių k.)

Polish (Polski)

Polish (Polski)

Portuguese (Português)

Portuguese (Português)

Romanian (Română)

Romanian (Română)

Russian (Русский)

Russian (Русский)

Serbian (Српска)

Serbian (Српска)

Slovakian (Slovenčina)

Slovakian (Slovenčina)

Slovenian (Slovenščina)

Slovenian (Slovenščina)

Spanish (Español)

Spanish (Español)

Turkish (Türkçe)

Turkish (Türkçe)