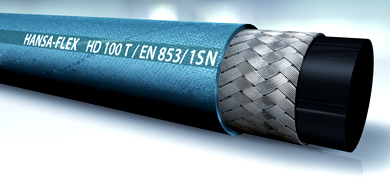

HD 100 T (1SN)

HD hose, high thermal resistance Product image

Product image

Properties

Properties

| Application |

Low and medium pressure circuits with extreme temperatures (e.g. foundries, compressors) Hydraulics in mechanical engineering |

| Special features |

outstanding ozone, weather, UV and temperature resistance |

| Standard |

EN 853 1 SN |

| Inner layer |

oil resistant synthetic rubber |

| Insert |

one high tensile steel wire braided insert |

| Outer layer |

synthetic rubber with high temperature, ozone and weather resistance |

| Colour |

blue |

| Temp. min. |

-55 °C |

| Temp. max. |

135 °C |

| Elongation |

+ 2 % to - 4 % |

| Media |

Mineral oil Gear oil Glycol and polyglycol Air-oil vapour Water-oil emulsion (0°C to +100°C) |

Note

Note

The change in length of the hose is determined at max. working pressure during testing to EN ISO 1402.

Operation with compressed air requires a perforated outer cover.

Item

Item

Sort upwards

Sort downwards

Identification Identification |

DN* | Size | Inches | Internal Ø min. (mm) |

Internal Ø max. (mm) |

Ø Insert min. (mm) |

Ø Insert max. (mm) |

External Ø max. (mm) |

Operating pressure (bar) |

Test pressure (bar) |

Burst pressure (bar) |

Min. bending radius (mm) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| HD 106 T | 6 | 4 | 1/4" | 6,2 | 7,0 | 10,6 | 11,6 | 14,1 | 225,0 | 450 | 900 | 100 |

| HD 108 T | 8 | 5 | 5/16" | 7,7 | 8,5 | 12,1 | 13,3 | 15,7 | 215,0 | 430 | 850 | 115 |

| HD 110 T | 10 | 6 | 3/8" | 9,3 | 10,1 | 14,5 | 15,7 | 18,1 | 180,0 | 360 | 720 | 130 |

| HD 113 T | 12 | 8 | 1/2" | 12,3 | 13,5 | 17,5 | 19,1 | 21,4 | 160,0 | 320 | 640 | 180 |

| HD 116 T | 16 | 10 | 5/8" | 15,5 | 16,7 | 20,6 | 22,2 | 24,5 | 130,0 | 260 | 520 | 200 |

| HD 120 T | 19 | 12 | 3/4" | 18,6 | 19,8 | 24,6 | 26,2 | 28,5 | 105,0 | 210 | 420 | 240 |

| HD 125 T | 25 | 16 | 1" | 25,0 | 26,4 | 32,5 | 34,1 | 36,6 | 88,0 | 175 | 350 | 300 |

DN = Nominal diameter, nominal width

Disclaimer

Despite careful checking, we cannot guarantee the accuracy of all information included on this site, and we accept no liability.

All data and information in our online catalogue are based on currently valid standards and the regulations from the employer's liability insurance association. Product safety can only be guaranteed when our assembly instructions are carefully observed. Non-adherence to these regulations can affect product operation and functioning and result in a loss of warranty. Our warranty is only valid for HANSA-FLEX products. Our products are constantly subject to further development and technical changes are therefore possible.

Select language

Select language

Bulgarian (Български)

Bulgarian (Български)

Chinese (汉语)

Chinese (汉语)

Croatian (Hrvatski)

Croatian (Hrvatski)

Czech (Čeština)

Czech (Čeština)

Dutch (Nederlands)

Dutch (Nederlands)

Estonian (Eesti)

Estonian (Eesti)

French (Français)

French (Français)

German (Deutsch)

German (Deutsch)

Hungarian (Magyar)

Hungarian (Magyar)

Italian (Italiano)

Italian (Italiano)

Latvian (Latviešu)

Latvian (Latviešu)

Lithuanian (Lietuvių k.)

Lithuanian (Lietuvių k.)

Polish (Polski)

Polish (Polski)

Portuguese (Português)

Portuguese (Português)

Romanian (Română)

Romanian (Română)

Russian (Русский)

Russian (Русский)

Serbian (Српска)

Serbian (Српска)

Slovakian (Slovenčina)

Slovakian (Slovenčina)

Slovenian (Slovenščina)

Slovenian (Slovenščina)

Spanish (Español)

Spanish (Español)

Turkish (Türkçe)

Turkish (Türkçe)